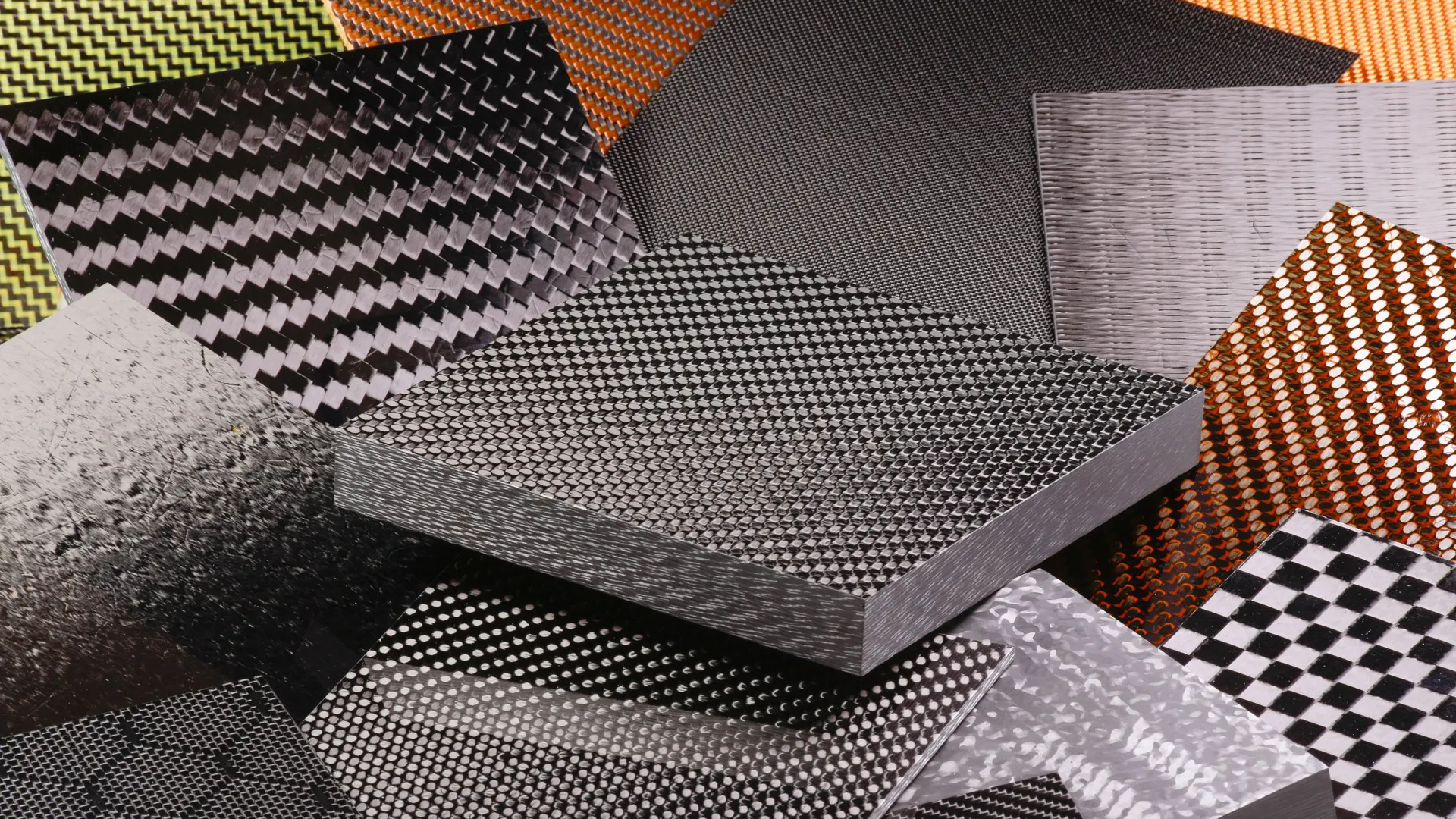

Signage & Graphics

Laser cutting technology plays a major role in today’s sheet metal industry, which promotes the development of sheet metal processing technology. Due to the advantages of flexible processing capability and high cutting precision, laser cutting machine is capable enough of handling any orders from large production to small batch orders.

Besides, laser cutting process enables sheet metal to be formed through one pass, so that sheet metal parts can be directly welded and assembled, greatly reducing the processing cycle and lowering the production cost.