Zhuoxing CNC Digital Knife Graphic Cutting Machine

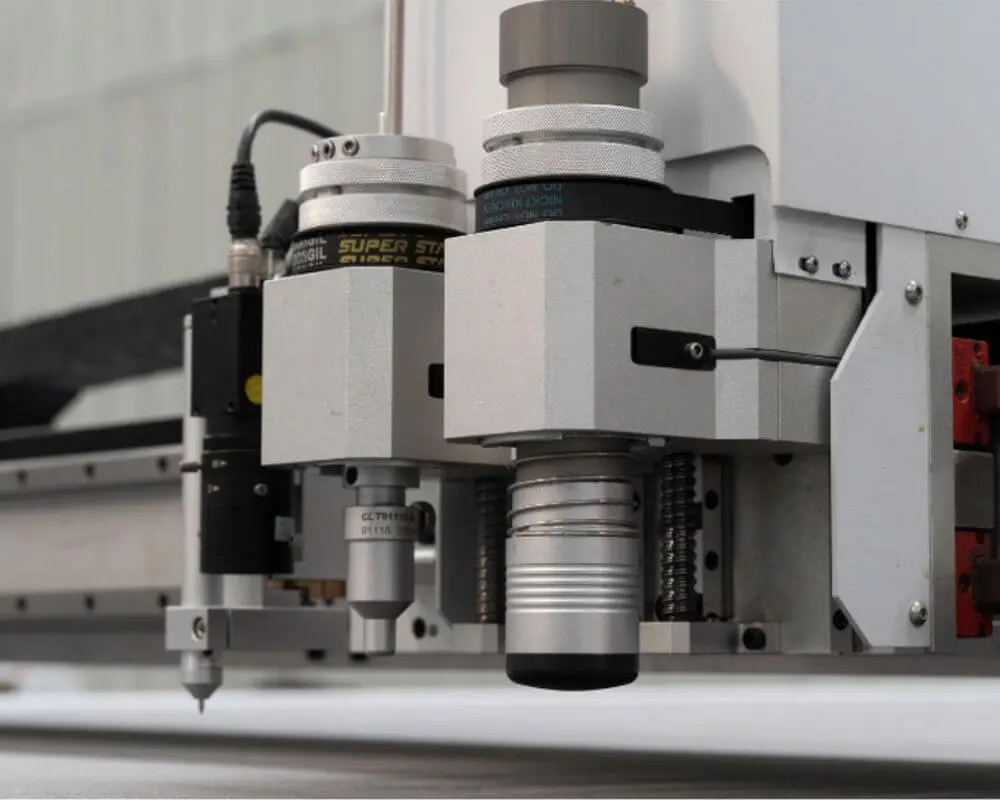

- High-precision cutting devices that use a computer-controlled cutting head to cut a wide range of materials, including foam, rubber, plastic, cardboard, and vinyl.

- Particularly useful for cutting advertising products such as billboards, banners, signs, and displays. They allow for precise, intricate cuts and can easily handle large volumes of material.

- Use advanced software to create cutting paths based on digital designs. This allows for rapid prototyping and fast turnaround times for production runs.

- Equipped with a variety of cutting tools, including oscillating knives, drag knives, and creasing wheels. This allows for versatility in cutting different materials and creating different shapes and patterns.

- A cost-effective solution for producing high-quality advertising products, as they require less labor and have lower material waste compared to traditional cutting methods.

Technical Data Of Zhuoxing’s Cutting Machine

| Model Area | ZX-0406VA | ZX-0608VA | ZX-1625VA |

|---|---|---|---|

| Working Area | 400*600mm | 600*800mm | 1600*2500mm |

| Max. Cutting Speed | 1400MM/S | Transmission System | Servo Motor,Linear Rail |

| Cutting Tolerance | ±0.1mm | Transmision Interface | Ethernet |

| Fixed Mode | Vacuum Absorb | Rated Power | 11kw |

| Operation Properties | Online/Offline Operation, 7*24hrs Continuous Cutting |

|---|---|

| Safety Device | Infrared Adopted, Sensitive Response |

| Materials Fit To Cut | Acrylic Board, KT Board, PVC Board, Vinyl, etc. |

| Functions | Cutting, Milling, Creasing, Nesting, etc. |

| Cutting Thickness | ≤25mm, Can be Customized For Thicker Material |

| Supply Voltage | AC 110V/220V/380V±10%, 50HZ/60HZ |

What Is A Cutting Machine For the Graphic Industry?

The CNC digital knife-cutting machine is a powerful, computer-based tool used to produce highly accurate results with speed and precision. This type of equipment has the capability to cost materials such as foam board, PVC, acrylics, and KT boards without sacrificing any quality in the outputted design. Using CAD software for programming operations beforehand allows operators time savings while having full control over their projects when they are put through this specialized machinery, making it invaluable within marketing agencies and other advertising-related industries.

| Available Knife Tool | Actual Image | Definition | Features |

|---|---|---|---|

| Oscillating Knife |  |

With its precise cutting technology, an oscillating knife – or vibratory knife – offers a more sophisticated and accurate approach to cut through various materials like foam, rubber, textiles and composite materials. | Precision cutting Versatility High-Speed Reduced waste Increased safety |

| Drag Knife |  |

A drag knife is an efficient and accurate cutting tool that can quickly slice through thin materials such as vinyl, cardboard, or paper. Its blade mounted on a holder creates precise parallel cuts in the material with ease. | Precision Cutting Versatility Cost-effectiveness Customization Time-sa |

Billboard Cutting

Sticker Cutting

Light Box Cutting

Acrylic Sheet Cutting

How Zhuoxing Digital Knife Cutting Machine Works

Why You Should Use Digital Knife CNC Cutter For Advertising

With its high-precision digital control system and incredible cutting speed, accuracy, and efficiency, the CNC Digital Knife Cutting Machine is revolutionizing the advertising industry. This state-of-the-art machine offers unparalleled versatility in creating intricate designs with various materials such as foam boards, corrugated boards PVC sheets, and acrylic sheets – enabling professionals in this field to bring their creative visions to life quickly and easily.

The CNC Digital Knife Cutting Machine is packed with impressive features that enable it to deliver precise and accurate results. Its digital control system ensures repeatable cutting, while its advanced software creates intricate designs which the machine executes flawlessly. Moreover, an automated tool change system permits rapid transitions between different tools, significantly reducing downtime for maximum productivity and efficiency.

For advertising professionals looking to take their craftsmanship and designs to the next level, CNC Digital Knife Cutting Machine is a must-have. This high-performance tool brings together its advanced functionality with an intuitive user interface for streamlined precision cutting of materials, making it a reliable go-to asset that keeps businesses one step ahead of competitors in today’s ever-changing market.

When You Need To Use Digital Knife Cutters

Working with a digital knife-cutting machine has its advantages. Beyond the obvious increase in production speed, you can enjoy an unprecedented level of precision and versatility when it comes to cutting all kinds of materials. Whether for fabrics, foam boards, or plastics – this tool is designed to deliver flawless results every single time!

- Versatility: Digital knife-cutting machines offer unbeatable versatility for a wide range of cutting requirements. From fabrics and foam to plastic, cardboard, and even wood – all materials can be handled with ease by digital knives. With this level of precision at your disposal it’s no surprise that more professionals are turning toward these revolutionary devices!

- Precision: With digital knife-cutters, creating intricate shapes with sharp lines and immaculate details is made effortless. Digital knife cutting guarantees impeccable results no matter the complexity of the design.

- Speed: Digital knife-cutting machines provide an efficient solution for quick and precise cuts, as their sharp blade is capable of making a clean cut in one pass.

- Cost: With lower equipment and maintenance costs, digital knife-cutters are the savvy choice for businesses or individuals to save on their cutting material expenses. Cost efficiency is one of the most attractive aspects when choosing a cutting machine, making digital knives an economical option.

- Safety: With their sophisticated blades, these digital systems present much less of an inherent safety risk compared to the high-powered lasers used for laser-cutting methods.