It is suitable for polyfiber sound-absorbing panels, sound-insulating cotton, felt, etc, It can realize various cutting functions such as slotting chamfering , straight cutting, and beveling. The bevel cut is generally 45 degree angle, 90 degree angle, 60 degree angle, 30 degree angle, 5 degree angle, etc, Precise cutting, saving material, Realize the transition of users from the traditional manual production and cutting mode to the high-speed, accurate and intelligent modem advanced production mode, and provide diversified and personalized cutting services.

ZXT has been committed to providing digital intelligent cutting solutions for users in the global sound insulation industry. The diversified digital cutting system can meet the processing needs of different materials and processes. For sound insulation boards, sound insulation cotton, insulation boards, and insulation cotton materials, whether it is personalized customization or mass production, ZXT can assist users to process high-quality products more quickly and accurately within a limited time and venue. The continuous creativity helps users quickly improve the competitiveness of the industry and lead the sound insulation industry to develop more healthily and steadily!

Support 24/7

Three years warranty

Customization and OEM

Application Samples

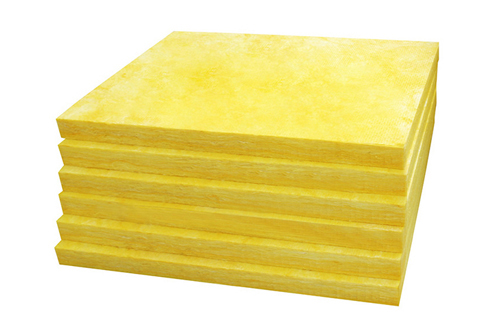

Glass fibre acoustic wool

Aluminium foil glass fibre insulation wool

Damping acoustic felt

Polyester fibre acoustic panels

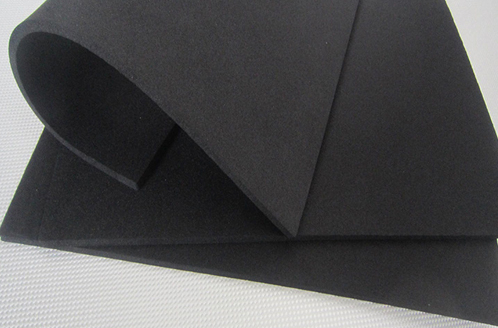

Rubber plastic acoustic wool

Flame retardant acoustic cotton

EPDM Acoustic Foam

Rock wool insulation board

Polyester acoustic wool

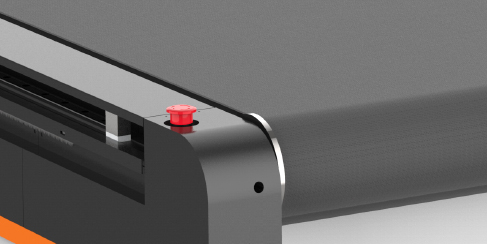

When precision and efficiency are paramount in cutting acoustic panels for walls, a CNC digital knife cutter is the ideal tool. This advanced technology ensures clean, accurate cuts that meet your exact specifications.

With your precisely cut acoustic panels ready, proceed to install them on the walls or surfaces where sound control is needed. Follow the installation guidelines specific to your acoustic panels and the project requirements. Using a CNC digital knife cutter ensures not only accurate cuts but also consistency and efficiency in producing acoustic panels for walls. Whether it’s for a home theater, recording studio, or office space, this method ensures your soundproofing solutions are tailored to perfection.

Start your journey

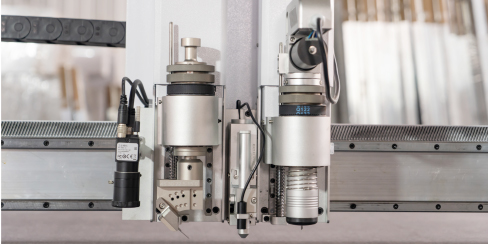

Recommended knives

Pneumatic knife

Vibrating knife

V groove knife

Recommended Models