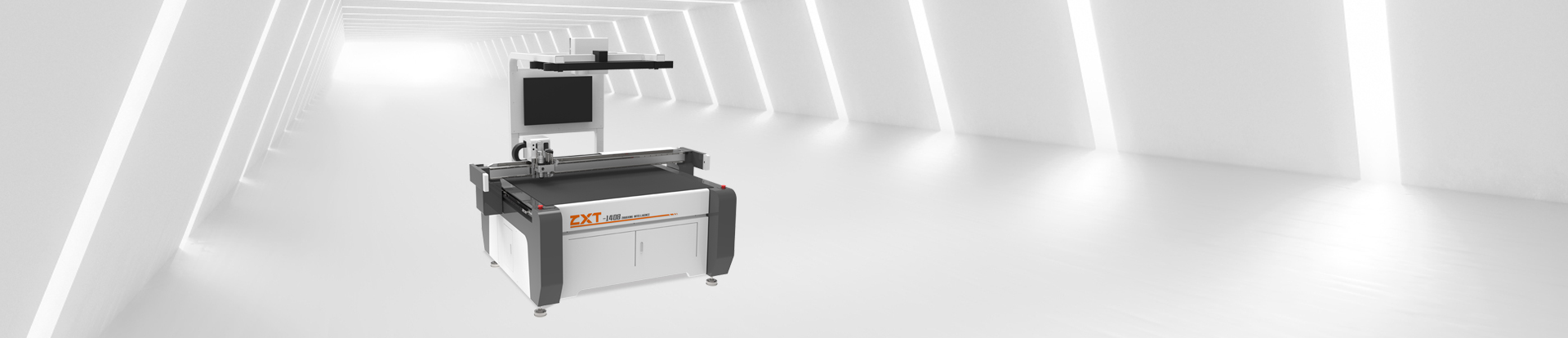

This machine is our latest smart cutting technology. A task that previously required 7 workers can now be completed by just one person. In the past, the company’s cutting equipment was time-consuming and labor-intensive, and the factory did its own printing and almost entirely relied on manual manufacturing.

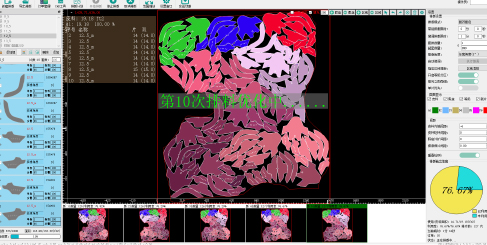

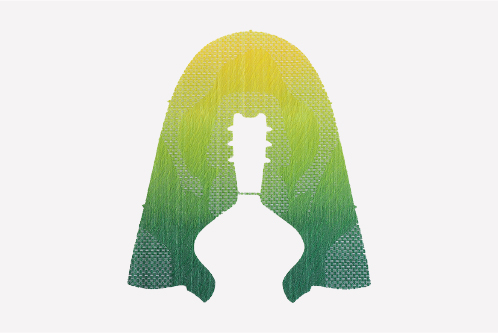

As the number of shoe models continues to increase, the production technology becomes increasingly sophisticated, and the requirements for shoe upper tailoring are also increasing, becoming more refined and stringent. Put a piece of shoe material into the machine, and the intelligent cutting machine can quickly cut out the upper of the sports shoe in a few seconds. Cutting The intelligent cutting machine can automatically identify and perform fine cutting, which significantly improves the utilization rate of raw materials. The machine can cut out complete uppers and soles accurately and quickly, greatly improving efficiency. Cutting intelligent cutting machines save a lot of labor costs and shorten the production cycle.

Support 24/7

Three years warranty

Customization and OEM

Core Benefits

Functional Features

- Save 100% of knife mold, save knife mold management personnel and space.

- Save 50% of skilled operators Automatic cutting instead of 2-3 laborers.

- No need to draw plate, data import one key cutting.

- High-quality cut pieces, can do difficult processes.

- Save 90% time than manual layout Increase 10% material utilization rate.

- High cutting precision, positioning accuracy ± 0.01mm.

- Smoke-free and odorless, blade cutting, more environmentally friendly.

- High cutting efficiency, running speed 350mm/s

- Leather automatic extraction contour cutting, intelligent avoidance of defects

- Customized models, support leather single and multi-layer cutting

- Adopt imported motor, more stable operation

- Self-developed high-performance integrated circuit, durable

- Honeycomb aluminum platform structure design, strong wind absorption capacity

Visual positioning system

Leather sofa

Leather belt

Leather bag

Leather jacket

Leather glove

Steering wheel

Application Samples

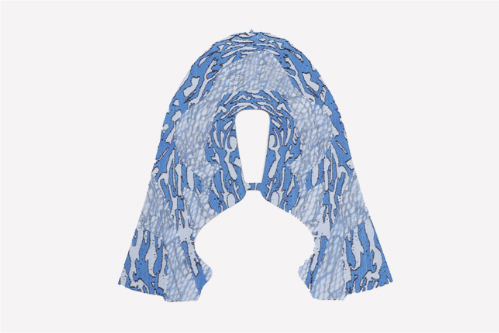

Fly-knitted shoes

Basketball shoes

Sandal

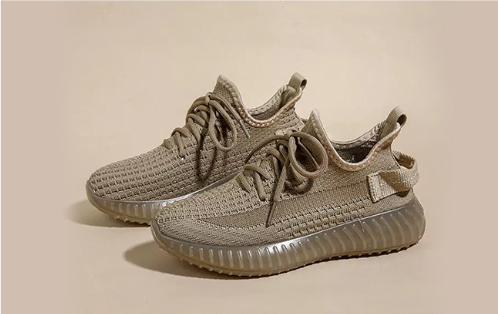

Sneaker

Sneakers

High heels

Mesh pedals

Leather shoes

Insole

Improve your production efficiency and flexibility in the footwear industry! Efficiently process leather, fabrics, soles, linings and template materials while ensuring the highest quality, eliminating the need for expensive cutting dies and reducing labor requirements. Excellent cutting performance, low operating costs and optimized workflow ensure a quick return on your investment.

Start your journey

Recommended knives

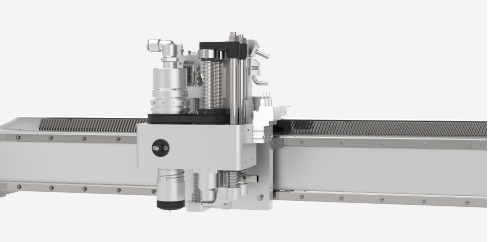

Pneumatic knife

Vibrating knife

Punching

Recommended Models