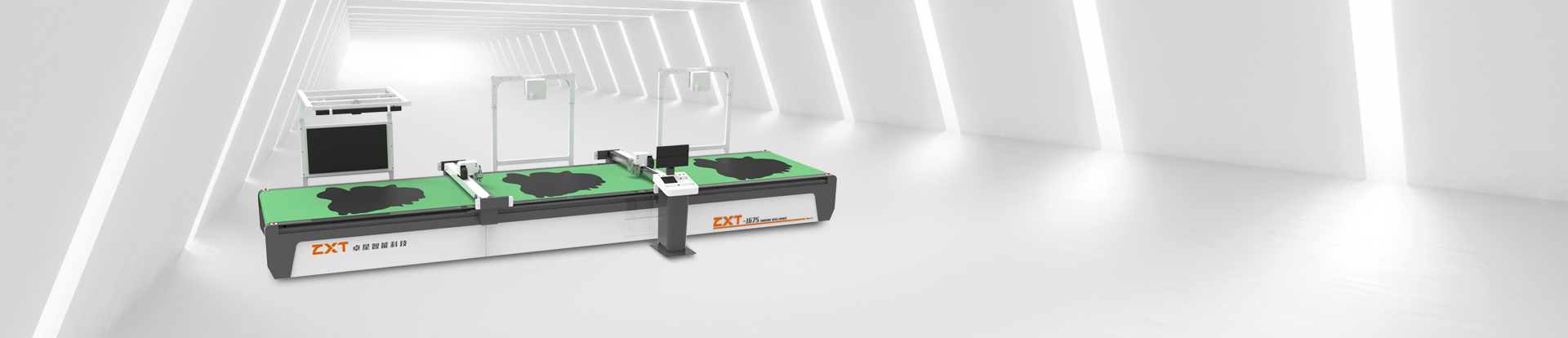

Cutting leather is a crucial step in making quality leather products. A cutting machine for cutting leather materials can help you achieve precision, speed, consistency, and versatility in your projects. When selecting a cutting machine, you need to consider the features, benefits, types, and factors outlined to make an informed decision. With the right cutting machine, you can take your leather crafts to the next level. One of the top benefits of using a digital knife cutting machine is improved efficiency. The machine can cut leather at a much faster rate than the traditional method, resulting in faster turnaround times and increased productivity. Digital knife cutting machines also offer precision cutting with clean edges that are not possible with hand-cutting tools. The machines can cut curved, straight, and intricate patterns with the utmost accuracy and consistency, ensuring that every piece of leather is cut with the same precision. Another significant benefit of digital knife cutting machines is the reduced waste generated during the cutting process. The machines can nest pieces of leather accurately, optimizing material usage and reducing wastage. In addition to reducing waste, the machines pose less risk of injury than traditional cutting tools, thus promoting workplace safety.

Support 24/7

Three years warranty

Customization and OEM

Core Benefits

Functional Features

- Save 100% of knife mold, save knife mold management personnel and space.

- Save 50% of skilled operators Automatic cutting instead of 2-3 laborers.

- No need to draw plate, data import one key cutting.

- High-quality cut pieces, can do difficult processes.

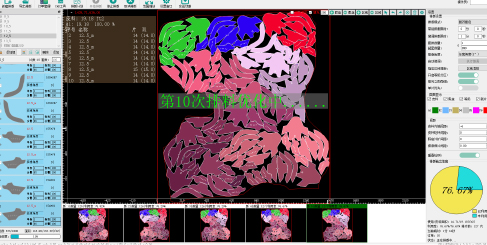

- Save 90% time than manual layout Increase 10% material utilization rate.

- High cutting precision, positioning accuracy ± 0.01mm.

- Smoke-free and odorless, blade cutting, more environmentally friendly.

- High cutting efficiency, running speed 350mm/s

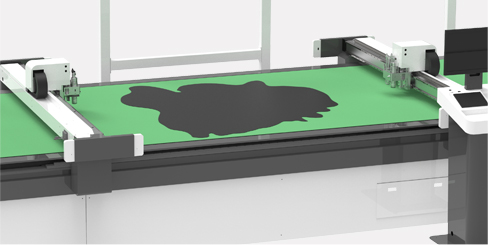

- Leather automatic extraction contour cutting, intelligent avoidance of defects

- Customized models, support leather single and multi-layer cutting

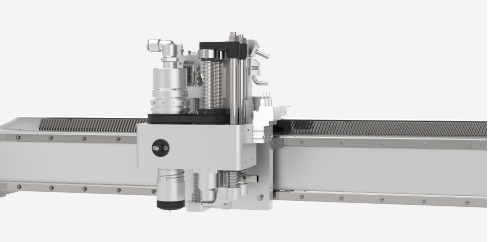

- Adopt imported motor, more stable operation

- Self-developed high-performance integrated circuit, durable

- Honeycomb aluminum platform structure design, strong wind absorption capacity

Application Samples

Leather sofa

Leather belt

Leather bag

Leather jacket

Leather glove

Steering wheel

Leather is a material that has been used for thousands of years to make various products such as bags, shoes, belts, and many more. However, cutting leather can be a challenging task, especially if you don’t have the right cutting tools. Manual cutting is often inaccurate and time-consuming, which can also be a source of frustration. Fortunately, with the advancement of technology, cutting leather has become much easier and more efficient, thanks to the introduction of the digital knife CNC cutter.

Start your journey

Recommended knives

Pneumatic knife

Vibrating knife

Punching

Recommended Models