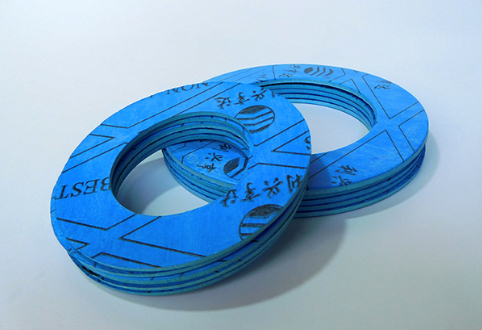

It mainly caries out automatic intelligent cutting of sealing materials,including asbestos-free sheets, asbestos, rubber sheets, silicone, graphite composite panels, PTFE, etc, The finished work has no sawtooth, no burrs, smooth and good consistency, effectively improves production efficiency, reduces the cost of punch cutting die, and helps customers in the sealing industry to win more market share with high quality, short production cycle and customized customer service while reducing costs and improving efficiency! CNC Gasket Cutting Machine is a computer-controlled cutting device that employs specialized software and precision machinery to fabricate gaskets of various shapes and sizes. Unlike conventional methods, where gaskets are hand-cut using templates, CNC machines follow digital designs with unparalleled accuracy. These machines operate on a subtractive manufacturing principle, where a gasket material is trimmed to the required shape by removing excess material.

Support 24/7

Three years warranty

Customization and OEM

Core Benefits

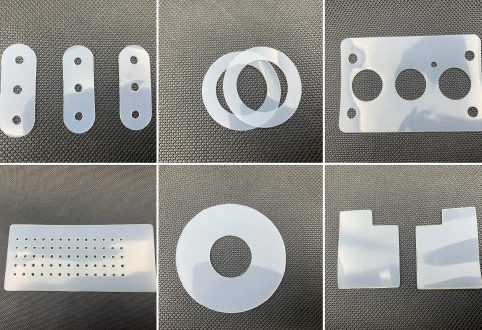

Application Samples

Felt gaskets

Cork spacer

Rubber gasket

Silicone gasket

Asbestos-free flange gasket

Non-asbestos gaskets

The automatic sealing gasket cutting machine does not need to be punched. It only needs to import the data into the system to identify and cut the material. The automation of this step directly saves a lot of time and cost.

The super nesting software is supplemented to complete the typesetting intelligently and accurately, without manual nesting. After a lot of tests, using the automatic cutting machine saves more than 10% of materials than manual labor. You can use this data to calculate how much you can save in a year.

Start your journey

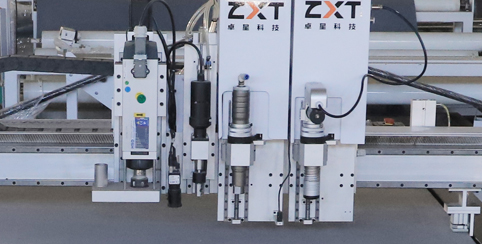

Recommended knives

Pneumatic knife

Vibrating knife

Milling spindle

Recommended Models