Description

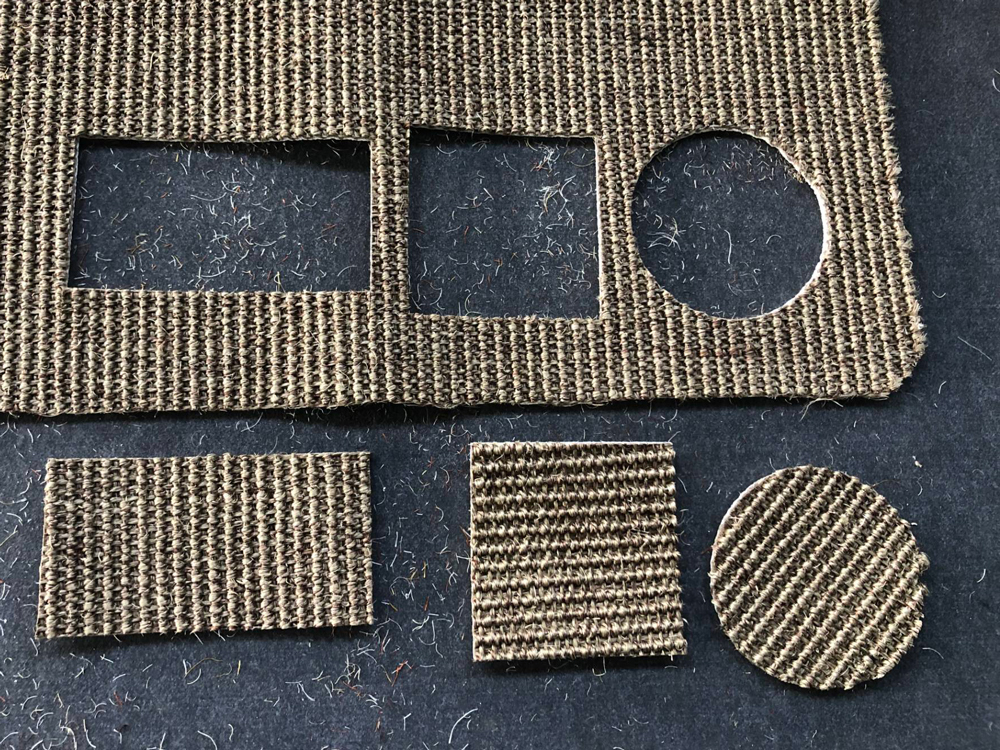

A variety of fabrics such as cotton, silk, denim, and leather can be effortlessly cut with precision by a CNC digital knife cutter.

Cloth Fabric Cutting Machine Video

Technical Data Sheet of Cloth Fabric Cutting Machines

| Model | ZX-1625VA | ZX-1830VA | ZX-3050VA |

|---|---|---|---|

| Working Area | 1600*2500mm | 1800*3000mm | 3000*5000mm |

| Cutting Thickness | 0.1mm-40mm | Max. Cutting Speed | 1200mm/s |

| Cutting Tolerance | ±0.1mm | Supported Format | DXF, PLT |

| Transmission Interface | Ethernet | Fixed Mode | Vacuum Absorb |

| Recommended Configuration | Cutting Tools, Punching, Ink, Auto Feeding | Function | Cutting, Punching, Auto Feeding |

| Materials Available For Cutting | Fabric, Cotton, Silk, Denim, Fur, Striped Fabric, etc. | ||

Cutting Tools For CNC Cloth Fabric Cutting Machines

Rotary Knife

Oscillating Knife

Pneumatic Knife

Punching

Inkjet

Auto Feeder

End Products Assisted By CNC Cloth Fabric Cutting Machines

Cloth Fabric Cutting Machine Application

Cloth

Clothing Customization

Fur

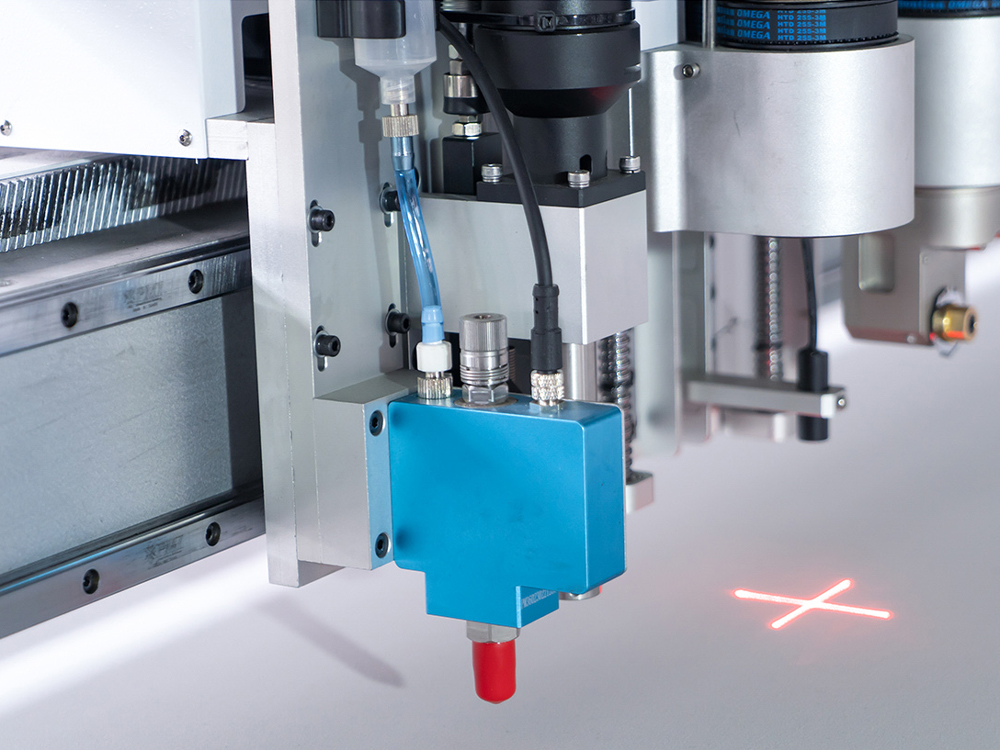

New Modular Tool Holder Design

New modular tool holder design

Installing tools much more easier, when customers increase product categories, customers only need to buy new needed tools. Provide convenience for customers to upgrade products. Compatible tools: Rotory Knife, Marking Pen, Auto Feeder, ect..

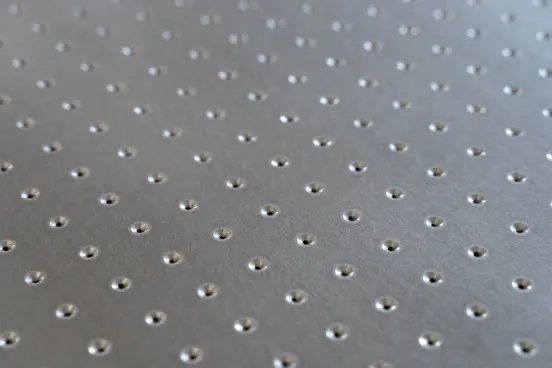

High precision aviation aluminum countertops

With the unique inner part of the wind structure, to ensure that each area of the platform suction even, more powerful suction.

Infrared Sensing Safety Device

Horizontal and vertical anti-collision protection is used to guarantee no blind angle is left uncovered. This will effectively protect operator’s safety.

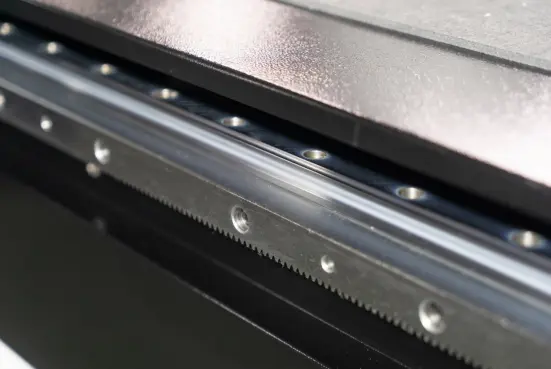

Pinion and rack

The equipment adopts rack and pinion transmission compared with belt transmission, which has large bearing capacity, high transmission accuracy, fast transmission speed and long service life.

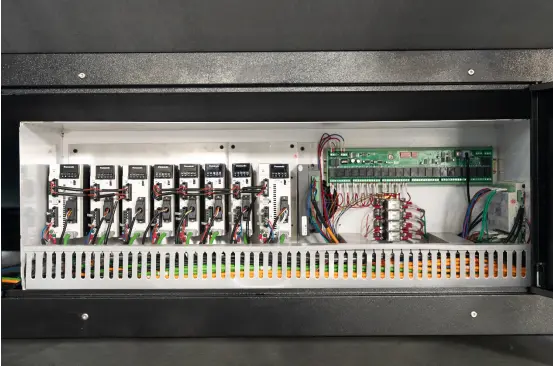

Distribution box

The CNC cutting machine fixes the control electrical box on the fuselage to avoid separation and cause line failure. All lines use high-flexibility cables, which have good wear resistance, moisture resistance, cold resistance and high temperature resistance.

Lathe bed structure

The whole machine adopts 5mm thick square tube, overall welding process, imported milling machine processing, to ensure the smoothness of the guide rail surface and rack surface, greatly improve the stability of the machine running time body.

Table Cloth

High-density felt can offer great maintien for material ensure each positioning is tightly fitted and protect the flatbed while cutting.

Panasonic Servo motor

Stable performance, high precision, low failure rate, high speed performance.

How to Cut Fabric with a CNC Digital Knife Cloth Fabric Cutting Machine?

Prepare the CNC Machine

- Load the appropriate cutting tool into the CNC machine, ensuring it’s clean and in good condition.

- Set up the computer that controls the CNC machine, ensuring the software is ready to receive your design.

Measure and Design

- Measure the dimensions you need for your fabric using a measuring tape.

- Use CAD software to design the cutting pattern or shape based on your measurements. Create a digital file of your design.

Program the CNC Machine

- Upload the digital design file to the CNC machine’s control software.

- Configure the cutting parameters, such as cutting depth and speed, to match the carpet and thickness.

Secure the Fabric

- Place the leather securely on the CNC machine’s cutting table. Ensure it’s flat and firmly positioned to prevent any movement during cutting.

- If necessary, use adhesive or clamps to hold the carpet in place.

Begin Cutting

- Start the CNC machine and initiate the cutting process. The machine will follow the programmed design, cutting the leather with precision.

- Monitor the machine during the cutting process to ensure everything runs smoothly and that the leather is cut according to your design.

Quality Check

- After the CNC machine completes the cutting process, carefully inspect the cut edges of the fabric. They should be clean, smooth, and free from any imperfections.

- Remove any remaining debris or loose particles from the fabric’s surface.

Apparel manufacturers can benefit from the expediency of CNC digital knife cutting machines. This technology enables designers to rapidly prototype their ideas and swiftly execute production runs, helping them bring products to market much faster than ever before!