Table of Contents

Introduction

CNC cutting machines are widely used in the manufacturing industry for cutting materials such as wood, metal, plastic, and more. With so many available options, choosing the suitable CNC cutting machine for your business needs can be daunting. However, it is crucial to invest in a suitable device as it can significantly affect the quality and efficiency of your products. In this blog post, we will provide you with a comprehensive guide to selecting the right CNC cutting machine that will meet your business needs.

Understanding Your Business Needs

Choosing the right CNC (Computer Numerical Control) cutting machine for your business can be a challenging task. With many options available on the market, it can be overwhelming to know what type of machine will best suit your business needs. That’s why it’s essential to understand your business before investing in a CNC machine.

Material Type and Thickness

The material type and thickness that your business works with will significantly influence the type of CNC cutting machine you’ll need. Some machines are better suited for thin sheets of metal, while others are ideal for thicker materials. Different machines are designed to handle different materials such as foam, wood, plastics, and even ceramics. Therefore, before investing in a CNC machine, it’s essential to determine the type of material that your business regularly works with.

Cutting Requirements

Each business has different cutting requirements. Some machines are designed for simple straight cuts, while others can cut complex 3D shapes and angles. For example, a business that deals with signage may require highly precise and intricate cuts, while a business that works with metal fabrication may require faster and more robust cutting capabilities. Therefore, it’s essential to identify your cutting requirements and choose a CNC machine that can meet those needs.

Production Volume

Another factor to consider is the production capacity of the CNC machine. Depending on your business’s production requirements, you may need a CNC machine that can handle high-volume production or one that can produce smaller batches at frequent intervals. Understanding your production volume and needs will help you choose a machine that can deliver the required output and meet your business goals.

Available Space

When selecting a CNC machine, it’s also crucial to consider the space available in your facility. Different machines come in varying sizes, so it’s essential to measure your space and choose a machine that can fit within your facility. Additionally, you may need to consider the ease of access and maneuverability of the machine.

Maintenance and Support

Lastly, maintenance and support are critical factors to consider when selecting a CNC machine. CNC machines are complex devices that require regular maintenance to keep them operating efficiently. Ensuring that your machine comes with adequate support and maintenance services can save your business time and money in the long run.

Choosing the right CNC cutting machine for your business doesn’t have to be a daunting task. By understanding your business’s unique needs and considering factors such as material type and thickness, cutting requirements, production volume, available space, and maintenance and support needs, you can choose a CNC machine that delivers the desired results. Doing your research and investing in the right CNC machine will ultimately help your business achieve its goals and ensure long-term success.

Different Types of CNC Cutting Machines

CNC cutting machines have revolutionized the manufacturing industry in many ways. These machines have made it possible for precision cutting and have significantly improved production efficiency. CNC machines offer a remarkable level of accuracy in cutting, and they work with computer-generated instructions. Manufacturing industries can use CNC machines to produce a wide variety of objects accurately and quickly, but it’s important to note that there are different types of CNC cutting machines for various purposes.

CNC Router Machines

CNC router machines are versatile machines capable of cutting, engraving, and carving different types of materials, including wood, plastic, and metal. CNC router machines have a fixed bed that moves vertically on a gantry, which carries the cutting tool horizontally. They are ideal for finishing complex designs since they provide high-speed cutting, high accuracy, and high-quality cuts. Router machines are popular in sign-making, custom woodworking, and complex cabinet manufacturing.

Plasma Cutting Machines

Plasma-cutting machines use a plasma torch to cut metals such as steel and aluminum. They work by ionizing the gas and then compressing it, which creates plasma that’s hot enough to melt metal. Plasma-cutting machines can work with a wide range of sheet thicknesses, and with the right settings, the resulting cut is clean and precise. Plasma-cutting machines are commonly used in construction, manufacturing, and metal fabrication.

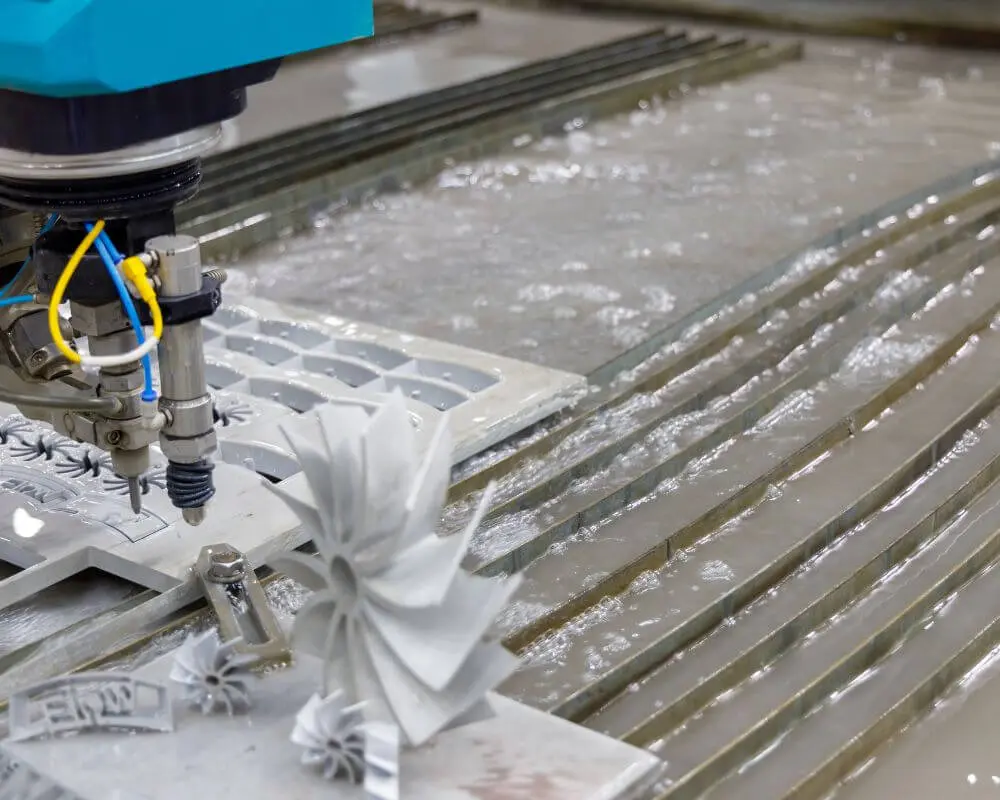

Water Jet Cutting Machines

Water jet cutting machines use a high-pressure stream of water mixed with abrasive materials like garnet to cut through materials like metal, glass, and stone. Water jet cutting produces highly accurate cuts, and it’s a cold cutting process, which means that there’s no heat affected zone. The versatility of water jet cutting machines means you can switch between various materials quickly, and you don’t have to worry about the material’s hardness. Water jet cutting machines are popular in aerospace engineering, automotive manufacturing, and architecture.

Laser Cutting Machines

Laser cutting machines use a laser beam that’s focused through a lens to cut, etch, and engrave materials. The beam cuts with accuracy and precision and it produces very consistent results. Laser cutting machines can work with a variety of materials, including glass, metal, plastic, wood, and paper. The precise cutting capability of laser cutting machines means they’re heavily used in prototyping, the metalworking industry, and jewelry-making shops.

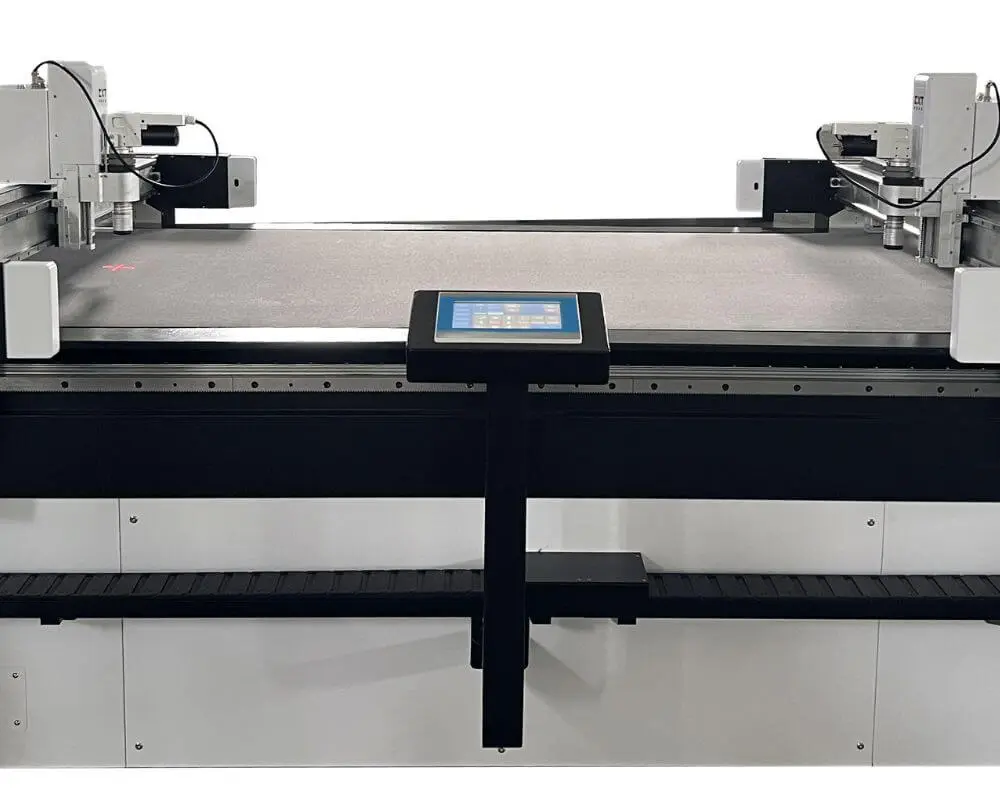

CNC Digital Knife Cutting Machines

Cutting and shaping various materials with precision has never been easier than with a CNC (Computer Numerical Control) digital knife cutting machine. Ideal for materials such as fabrics, foams, plastics, leather, and composites, this specialized piece of equipment utilizes computer-controlled movements and a digital knife tool for accuracy.

Using a computer program that contains instructions for desired cuts, the machine’s cutting process is guided. The user can create or import a design, and specify cutting paths, cutting depth, and speed with CAD (Computer-Aided Design) software.

For cutting, this machine uses a sharp oscillating or vibrating blade that moves back and forth or up and down. Computer-controlled motorized systems monitor the blade, allowing the machine to cut intricate shapes with high accuracy and repeatability.

The advantages of the CNC digital knife cutting machine are many. Production speed increases, manual labor reduces, material waste minimizes, and this device allows the creation of complex shapes and designs. Furthermore, the CNC system can program the machine to crease, perforate, engrave, and even draw beyond cutting purposes.

Industries such as apparel, automotive, aerospace, signage, packaging, and upholstery utilize the CNC digital knife cutting machine due to its versatility and efficiency for precision cutting and customization.

Consider Machine Bed Size

CNC cutting machines have revolutionized the manufacturing industry. They have made it possible to create complex shapes and designs with precision and accuracy. However, when choosing a CNC cutting machine, one of the most important factors to consider is the machine bed size. The machine bed size determines the size of the materials that can be cut, which in turn, affects the efficiency and productivity of your manufacturing process.

Consider the size of your materials and projects

The first factor to consider when choosing a machine bed size is the size of your materials and projects. If you work with smaller materials, such as jewelry or electronic components, a smaller machine bed may suffice. However, if you work with larger materials, such as sheets of metal or wood, you will need a larger machine bed. Additionally, if you work on large projects, a larger bed may be necessary to complete the job efficiently.

Think about the future

When choosing a machine bed size, it’s important to think about the future of your business. Do you plan to expand your production line and work on larger projects in the future? If so, it may be a good idea to invest in a larger machine bed now, rather than having to upgrade later. However, if you don’t foresee a need for a larger bed in the future, a smaller one may be more cost-effective.

Consider your budget

Machine bed size is directly related to the cost of a CNC cutting machine. Larger machine beds are more expensive than smaller ones, and your budget will undoubtedly be a factor in your decision-making process. It’s important to find a balance between your production needs and your budget. If you work with larger materials, you may need to invest in a larger bed, but that investment may lead to increased productivity and profitability in the long run.

Think about space requirements

Another factor to consider when choosing a machine bed size is the amount of space you have available in your facility. If you have limited space, a smaller machine bed may be the most practical choice. However, if you have ample space, a larger bed may be more efficient, enabling you to cut larger materials without having to repeatedly reposition them on the bed.

Look for versatility

Finally, when choosing a machine bed size, it’s important to look for versatility. Some CNC cutting machines have interchangeable machine beds, which can be swapped out to accommodate different materials and projects. This feature can increase the versatility and flexibility of your CNC cutting machine, allowing you to work on a variety of projects with ease.

Choosing the right machine bed size is an important decision when purchasing a CNC cutting machine. It’s essential to consider your production needs, budget, space requirements, and your future business growth. By taking these factors into account, you can select the best machine bed size for your needs, ensuring optimal efficiency and productivity. Remember, the right machine bed size can make a significant difference in the success of your manufacturing process.

Look at Machine Accuracy and Speed

In any production process, accuracy and speed are two crucial factors that determine the quality of the output and the efficiency of the business. Machines that offer high accuracy and speed can make a significant impact on the productivity and profitability of a business, while machines that lack these features can lead to subpar results and hinder growth opportunities.

Accurate Machines

Precision is a critical requirement of many industries such as aerospace, medical, and manufacturing. A machine with high accuracy ensures that the output meets the required standards and detects faults in the production process. For instance, CNC machines offer precision in cutting materials, and automated inspection systems can identify errors in the product. Therefore, investing in a highly accurate machine means consistent quality output, minimal material wastage, increased production capacity, and customer satisfaction.

Speed of Machines

Speed is another crucial factor in the production process. Productivity is usually measured in output per unit of time, and a high-speed machine can increase your production capacity and reduce turnaround time. For example, in the food industry, faster-filling machines increase the output of packaging and reduce the waiting time between batches. However, the speed of the machine is subject to limitations such as strain on the machine, potential errors, and the complexity of the operation. Therefore, before choosing a high-speed machine, it is necessary to consider the nature and requirements of your business.

The balance between Accuracy and Speed

While both accuracy and speed are essential, there is a tradeoff between the two. A highly accurate machine may compromise speed, while a high-speed machine might compromise accuracy. Therefore, finding the right balance between these two features is crucial for achieving optimal results and maximizing profits. You need to consider the type of industry, production requirements, customer demands, and cost of operation before making a decision. Also, consider the maintenance and reliability of the machine to ensure long-term performance.

Advancements in Technology

With advancements in technology, machines are becoming more accurate and faster than ever before. Manufacturers are developing innovative machines that can perform multiple tasks in one unit, reducing labor costs, and increasing output. For instance, a robotic arm can perform different tasks such as welding, cutting, and lifting. Many machines are now equipped with sensors and control systems that measure performance, such as vibrations, temperature, and pressure. This technology enables operators to monitor and adjust the machine in real time, enhancing accuracy and speed.

Accuracy and speed are essential features that impact the success of any business. A highly accurate machine can provide consistent quality output, while a high-speed machine can increase productivity and reduce turnaround time. However, finding the right balance between these two features is crucial for achieving optimal results. Advancements in technology provide innovative solutions that improve accuracy and speed, leading to increased efficiency, reduced labor costs, and better customer satisfaction. Therefore, investing in a machine that offers a balance between accuracy and speed based on your business requirements can give you a competitive edge in the market.

Consider Price and Maintenance

Investing in a new machine is a big decision, both financially and operationally. It can be tempting to go for the cheapest option or the latest and greatest technology, but there are more factors to consider beyond just the initial purchase price. One such factor is maintenance costs and requirements. In this part, we’ll explore why it’s important to consider price and maintenance when buying a machine, and how to find a balance that meets your production needs and budget constraints.

The True Cost of Ownership

When considering the price of a machine, it’s important to look beyond just its purchase price. The true cost of ownership includes maintenance, repair, and replacement costs, as well as energy usage, downtime, and labor costs. A higher initial purchase price may actually end up being more cost-effective in the long run if it requires less maintenance and repair, lasts longer, and operates more efficiently. On the other hand, a cheaper machine may end up costing more in the long run if it requires costly repairs and frequent maintenance.

Maintenance Requirements

Different machines have different maintenance requirements, depending on their complexity, age, and usage. Some may require regular cleaning, lubrication, adjustment, calibration, or replacement of parts, while others may require specialized skills, tools, or training. Before buying a machine, it’s important to research its maintenance requirements and costs and to make sure you have the necessary resources and expertise to maintain it properly. Neglecting maintenance can lead to decreased efficiency, increased downtime, and premature breakdowns, which can be costly and disruptive to your production.

Predictive vs Reactive Maintenance

There are two main approaches to maintenance: predictive and reactive. Predictive maintenance involves monitoring a machine’s performance and condition, analyzing data, and taking proactive measures to prevent problems before they occur. It can be more cost-effective in the long run, as it helps to minimize downtime, repair costs, and production losses. Reactive maintenance, on the other hand, involves waiting for a problem to occur before taking action, which can result in increased downtime, repair costs, and production losses. When choosing a machine, it’s important to consider its potential for predictive maintenance and to invest in the necessary tools and technologies to support it.

Balancing Price and Maintenance

Finding a balance between price and maintenance can be a challenge. On one hand, you want a machine that meets your production needs and budget constraints, but on the other hand, you don’t want to compromise on quality or reliability. One way to achieve this balance is to do your research and compare different machines based on their total cost of ownership, maintenance requirements, and potential for predictive maintenance. You can also consult with industry experts, read reviews, and visit manufacturer websites to get a better sense of what to look for in a machine.

When it comes to buying a machine, the price may be a primary consideration, but it’s not the only one. Maintenance costs and requirements can have a significant impact on the total cost of ownership, efficiency, and lifespan of a machine. By considering both price and maintenance when choosing a machine, you can find a balance that meets your production needs and budget constraints, while also ensuring optimal performance and reliability. Doing your research, seeking expert advice, and investing in predictive maintenance can help you make an informed and cost-effective decision.

Conclusion

Choosing the right CNC cutting machine can be a challenging task, but with the right information, it can also be a rewarding one. By considering your business needs, researching different types of CNC machines, and evaluating machine bed size, accuracy, speed, price, and maintenance, you can find a machine that will help you achieve your business goals. If you’re still unsure about which machine is right for you, consult with a CNC machine specialist who can provide you with additional insights and advice.