Table of Contents

Are you a fan of DIY projects and big on creating your own custom pieces? If so, you may have looked into using laser cutters or engravers to achieve your desired results. While this type of tool is invaluable for anyone looking to craft beautiful pieces using the latest technology, potential safety risks should always be taken into consideration when working with lasers. In this blog post, we’ll delve deeper into understanding how dangerous laser cutters and engravers can be and what rules need to be followed in order to ensure that everyone works safely when handling them.

Introduction

A brief overview of laser cutters, engravers, and CNC digital knife cutting machines

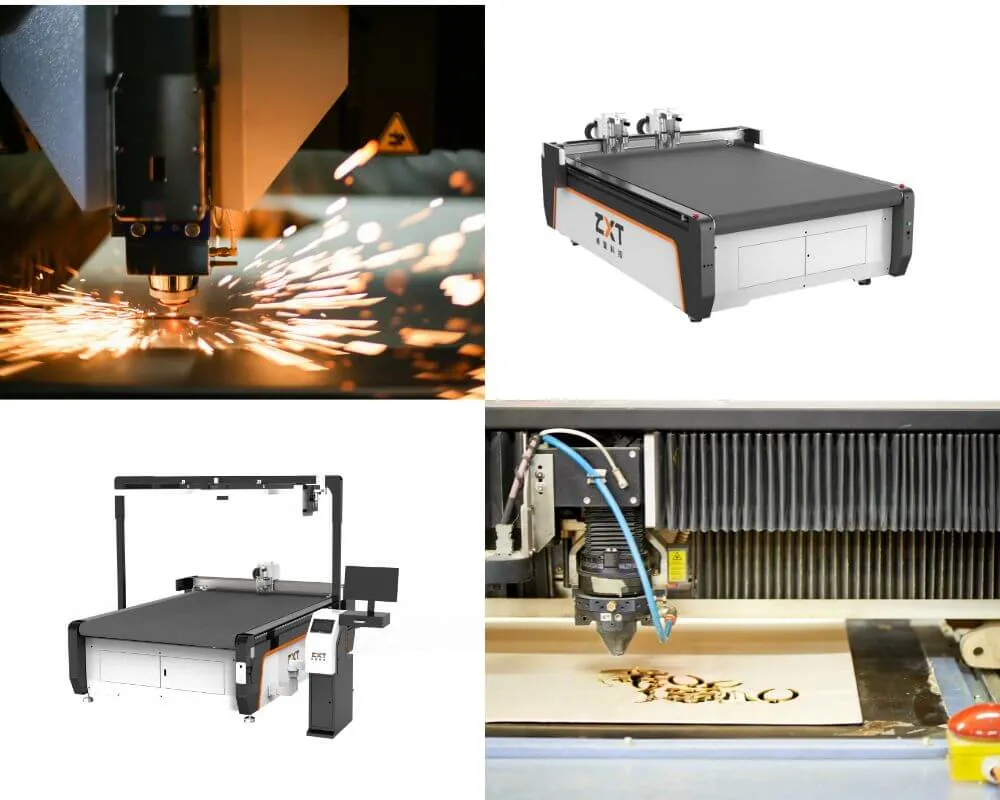

Laser cutters, engravers, and CNC digital knife cutting machines are all modern marvels that have revolutionized the way we create objects. Laser cutters work by emitting a highly focused beam of light that vaporizes the material it comes in contact with. This allows for precise cuts and intricate designs that are impossible to achieve with traditional cutting methods. Engravers, on the other hand, use a laser to etch designs and patterns onto surfaces. CNC digital knife cutting machines use a computer-controlled blade to cut through a variety of materials. The versatility and precision of these machines make them invaluable in a range of industries, from manufacturing to fashion design. If you’re looking to create something that requires a delicate touch or intricate design, one of these machines might just be the key to unlocking your creativity.

Why these machines are becoming increasingly popular

In recent years, there has been a surge in the use of machines for different purposes. From manufacturing to home appliances, machines are becoming indispensable in our daily lives. The reason for this trend is not far-fetched. Machines are not only efficient but also cost-effective, saving time and resources. In the workplace, machines carry out repetitive tasks with precision, allowing for increased productivity. In the home, machines automate household chores, leaving us with more leisure time. Furthermore, advancements in technology have made machines smarter and more versatile, capable of handling complex tasks that were once the exclusive preserve of humans. As such, it is reasonable to expect that the popularity of machines will continue to rise, as more people recognize the need for these devices in their lives.

Potential hazards of laser cutters and engravers

Laser cutters and engravers are powerful machines that can create intricate designs and shapes with ease. However, it’s important to remember that these machines also come with potential hazards. The intense heat and light from the laser can cause severe burns and eye damage if proper safety measures are not taken. In addition, laser cutters and engravers can also release toxic fumes and particles into the air, which can be harmful to your health if inhaled. It’s crucial to always wear the necessary protective gear, such as goggles and respirators, and to use these machines in a well-ventilated area to minimize any risks. By taking these precautions, you can safely enjoy the benefits of laser technology without any dangerous consequences.

-

Fire hazards

Laser cutting and engraving are wonderful methods for creating personalized designs on a range of materials, including jewelry and wooden furniture. But there is an inherent danger in the form of a potential fire hazard that must not be overlooked. Laser machines can generate enough heat to set fire to flammable materials, posing a grave safety concern. Therefore, caution and proper ventilation measures should be taken to ensure that unwanted incidents do not occur. Nevertheless, by taking necessary safety precautions, artists and designers can keep reaping the multiple advantages of laser cutting and engraving while mitigating the risk of fire hazards.

-

Eye damage

Laser cutting machines and engravers have transformed industries through their remarkable precision and efficiency. However, it’s essential to understand the inherent dangers associated with operating these machines. The risk of eye damage is particularly worrisome as the strong beams of light can cause permanent harm. Many operators underestimate the required level of protection, making it imperative to wear proper eye protection and observe safety protocols, keeping oneself and others secure. Neglecting safety measures can lead to a lifetime of regret, so always keep your eyes protected.

-

Electrical hazards

Revolutionizing precision and speed in the manufacturing industry, laser cutting machines and engravers have transformed production methods. However, increased risk of electrical hazards accompanies these innovative machines. The massive heat and voltage generated can lead to dangerous electrocution and short circuits. Comprising flammable materials increases the threat of hazardous ignition. In light of these hazards, ensuring workplace safety necessitates taking necessary precautions–grounding the equipment and keeping it away from any flammable substances is critical. Make safety paramount.

-

Chemical exposure

Using laser cutting machines and engravers can result in chemical exposure. The use of these tools can release harmful chemicals that are hazardous to both the environment and human health. It is imperative to be aware of the potential dangers that come with operating these machines and take proper precautions to ensure safety. Some common chemicals used in laser cutting and engraving include cyanide, formaldehyde, and nitrogen oxides. Regularly monitoring and maintaining these machines are essential in preventing excessive exposure to these chemicals. By implementing safety measures, we can reduce the risk of chemical exposure and ensure a safe working environment for everyone.

-

Mechanical hazards

These machines offer unparalleled efficiency and precision, capable of slicing through thick materials in seconds. However, beware: incorrect usage can lead to serious mechanical hazards such as electrocution, and skin burns. Always prioritize safety by wearing proper gear and adhering to operating instructions meticulously. By doing so, you can shield yourself from harm and keep producing intricate designs with these powerful tools.

https://www.youtube.com/watch?v=DuyzWaYDXPg

(Youtube Channel: @makeorbreakshop)

Safety measures to minimize hazards

When it comes to using laser cutting machines or engravers, safety should always be a top priority. These machines produce incredibly powerful beams of focused light, which can cause serious harm if not handled correctly. Fortunately, there are many safety measures that can be taken to minimize the risks associated with laser cutting and engraving. For example, operators should always wear protective eyewear to shield their eyes from intense light. Additionally, the area around the machine should be carefully marked and secured to prevent unauthorized access. With the right precautions in place, laser cutting and engraving can be a safe and rewarding way to create intricate designs and shapes.

Following safety protocols and guidelines

Working with laser cutters and engravers can be an exciting and rewarding experience, but it’s important to remember that safety should always be a top priority. These machines use intense beams of light to cut and engrave a wide range of materials, and if not used properly, they can pose a serious risk of injury. That’s why it’s crucial to follow all safety protocols and guidelines when using laser cutters and engravers. Make sure to read the manufacturer’s instructions carefully, wear appropriate safety gear such as safety glasses and gloves, and avoid touching the machine while it’s in operation. By following these precautions, you can enjoy the benefits of these incredible tools without putting yourself or others in harm’s way.

Proper training for operators

Operating a laser cutting machine or engraver is a highly specialized skill that demands proper training. This type of equipment is complex, sophisticated, and potentially hazardous, and it’s crucial for operators to understand how to handle the machine safely. The training provides all the necessary knowledge and skills to properly operate the machine, from how to set it up for a job to programming and controlling it. Proper training ensures that the operators understand the machine’s features and its potential hazards, as well as how to troubleshoot any issues that may arise. With the right training, there is no limit to what can be achieved with a laser cutting machine or engraver.

Regular maintenance and inspection

Laser cutting machines and engravers are valuable tools for fabricators and manufacturers all over the world. These devices utilize highly-concentrated beams of light to cut and mark materials with a level of precision that traditional tools simply cannot match. However, without proper maintenance and inspection, these machines can lose effectiveness and even break down entirely. That’s why it’s critical to perform regular maintenance and inspection on your laser cutting equipment. By doing so, you can maximize its lifespan and ensure that it operates efficiently and reliably for years to come. From ensuring that all components are tightened and calibrated correctly to replacing worn-out parts, taking the time to maintain and inspect your equipment is an investment in both quality and longevity.

Proper use of personal protective equipment (PPE)

Personal protective equipment, or PPE, is a crucial aspect of workplace safety. Whether it’s gloves, masks, or safety goggles, PPE provides a barrier of protection against injury and illness from potentially hazardous materials. It’s important to understand not only what PPE is available, but also when and how it should be worn. Proper use of PPE can prevent accidents and injuries, keeping workers safe on the job. Employers have a responsibility to provide the necessary equipment and training to ensure their workers are using PPE correctly. By following guidelines and using PPE as intended, we can create safer work environments for everyone.

Emergency response plans

Emergencies can strike at any time, and it’s important to be prepared. That’s where emergency response plans come in. These plans help organizations, businesses, and individuals navigate unforeseen crises by outlining the steps they need to take to protect themselves and others. From natural disasters to public health emergencies, having a clear plan in place can make all the difference in ensuring everyone stays safe and secure. By taking the time to develop and practice emergency response plans, we can all be better equipped to handle whatever challenges may come our way.

The importance of safety when using laser cutters and engravers

Laser cutters and engravers are becoming increasingly popular in various industries nowadays, whether it’s for creating signage, jewelry, or artwork. However, one cannot disregard the safety concerns surrounding the use of these powerful machines. It is essential to prioritize safety when operating a laser cutter or engraver – not just for the operator’s sake but also for anyone in the vicinity. Failure to observe proper safety measures can lead to accidents and injuries, such as burns, eye damage, and even fires. It’s crucial to take time to understand the safety protocols when using these machines and always wear appropriate protective gear. Remember, safety should be the top priority to ensure a successful and risk-free laser cutting and engraving experience

Consequences of not following safety protocols

When it comes to safety, it’s common knowledge that following protocols is crucial. However, what many don’t realize is the heavy toll that negligence can take on individuals and entire organizations. Not only does not following safety protocols put workers at risk of injury or even death, it can also lead to costly lawsuits, damaged reputations, and loss of business. Additionally, a workplace accident can have a profound impact on the mental and emotional well-being of everyone involved. So, while it may seem inconvenient or time-consuming to follow safety protocols, the consequences of not doing so are far too severe to ignore. It’s imperative that we prioritize safety in every aspect of our lives to better protect ourselves and those around us.

The need for proper safety measures in the workplace

In today’s fast-paced manufacturing industry, laser cutting machines and engravers play a crucial role in creating precision cuts and designs. However, with great power comes great responsibility. These high-powered machines can cause severe injuries if proper safety measures are not in place. It is essential for employers to prioritize the safety of workers by implementing safety protocols, conducting regular training sessions, and providing protective gear. Workers must also be mindful of the risks involved and take necessary precautions to avoid accidents. By ensuring a safe working environment, we prioritize the well-being of our workforce while also maintaining productivity and efficiency.

Advantages of using CNC digital knife cutting machines for cutting things

The world of manufacturing and cutting is changing with the introduction of CNC digital knife cutting machines. These machines use advanced technology to create precision cuts for a wide range of materials, allowing businesses to streamline their production processes and reduce waste. The advantages of using CNC digital knife cutting machines are endless. They can cut a variety of materials ranging from rubber, fabric to composite materials. Due to their precision, they can make complex cuts that were once impossible, ensuring that your products have a professional finish. This technology is incredibly efficient, reducing production times while maintaining accuracy. The machines are also incredibly easy to operate and maintain, making them an excellent investment for any business looking to modernize their operations. Overall, the advantages of using CNC digital knife cutting machines are numerous, and businesses that adopt this technology will certainly reap the rewards.

-

Precision

In today’s ever-evolving world of technology, precision is key. This is especially true when it comes to CNC digital knife cutting machines. These machines provide businesses with the ability to create highly accurate and intricate designs to be cut into a variety of materials, such as cardboard, foam, and leather. With computer programs controlling the machines, the level of precision is unmatched. These machines are perfect for businesses looking to create custom pieces with complicated designs or those who need a large volume of identical pieces. By using CNC digital knife cutting machines, businesses can guarantee that their products will be consistent and precise, improving efficiency and customer satisfaction. Overall, these machines offer a multitude of benefits for businesses looking to take their production process to the next level.

-

Speed

In today’s fast-paced world, time is of the essence. With technological advancements, businesses can now complete tasks faster than ever before. The CNC digital knife cutting machine is a prime example of this phenomenon. This cutting-edge technology allows businesses to complete intricate cuts with speed and precision, saving precious time and increasing productivity. Gone are the days of manual cutting, which was not only time-consuming but also prone to errors. With the CNC digital knife cutting machine, businesses can cut materials such as foam, fabric, composite materials, and leather materials with ease. The speed and accuracy of this machine have remodeled the manufacturing industry, making it an essential tool for any business that values speed and efficiency.

-

Efficiency

Efficiency is the name of the game when it comes to manufacturing. The rise of CNC digital knife cutting machines has made it easier and faster than ever before to cut and shape materials with precision. These machines are designed to handle a variety of tasks while reducing wasted materials and streamlining the production process. With such innovation, businesses can now save valuable time, labor costs, and boost productivity. The ability to quickly create customized products with accuracy and speed has revolutionized the industry and allowed for more creative and diverse manufacturing options. In a world where time is money, CNC digital knife cutting machines are a game-changing technology that can help businesses improve their bottom line.

-

Versatility

Save valuable time in your production process with the versatile precision of CNC digital knife cutting machines. These machines can expertly handle a wide range of materials, from foam to leather, making them the perfect tool for businesses that produce different products. With their ability to execute complex designs with laser-like accuracy, CNC digital knife cutting machines empower manufacturers to deliver quality products within tight deadlines. Whether you’re creating custom footwear or automotive upholstery, trust these machines to get the job done with minimal hassle. Join the many businesses who have already embraced the unparalleled versatility of CNC digital knife cutting machines.

-

Customization

In today’s business world, standing out is crucial to success. One way to achieve this is through customization, and CNC digital knife cutting machines make it possible. These machines offer unparalleled precision, allowing for intricate and personalized designs across a range of materials. Whether you need to create packaging or upholstery, CNC digital knife cutting machines can deliver flawless results. What’s more, they can be programmed for consistent output, perfect for mass production. With customization becoming increasingly important, investing in these machines could be the game-changer your business needs to elevate your products to the next level.

https://www.youtube.com/watch?v=A7MzYHrX2Uc

Comparison of laser cutters and CNC digital knife cutting machines

When it comes to cutting and engraving materials, there are two main options: laser cutters and CNC digital knife cutting machines. Laser cutters utilize a high-powered laser beam to precisely cut or engrave a wide range of materials, while CNC digital knife cutting machines use a computer-controlled knife blade to cut through materials such as foam, cardboard, and fabric. While both machines offer their own unique advantages and disadvantages, the decision ultimately comes down to the specific needs of the user. Laser cutters are better suited for detailed designs while CNC digital knife cutting machines are better for cutting thicker materials. In the end, it’s important to weigh all options to determine which machine best fits your needs.

Why CNC digital knife cutting machines may be a safer alternative

CNC digital knife cutting machines have been increasingly preferred over traditional cutting machines due to their precision and cost-effectiveness. However, they are also safer alternatives that prevent work-related accidents from happening. Unlike manual cutting methods, digital knife cutting machines are programmed to cut materials with utmost accuracy, minimizing the risk of human error. Furthermore, these machines are equipped with intelligent sensors that detect any malfunction or deviation from the cutting plan, immediately stopping the process to prevent damage or injuries. Whether you’re dealing with soft textiles or hard materials, CNC digital knife cutting machines offer a safer and smarter solution that increases efficiency and productivity while reducing workplace hazards.

Conclusion

Recap of potential hazards and safety measures for laser cutters and engravers

Laser cutters and engravers are powerful tools that have revolutionized the world of crafting and design. However, these machines require thorough safety precautions to avoid potential hazards. Burns, electrocution, and exposure to fumes are among the most common risks associated with laser cutters and engravers. It is essential to wear protective gear such as gloves, goggles, and face shields when operating these machines. Adequate ventilation and proper training are equally important for safe operation. Remember to always disconnect the machine from power when not in use, and ensure that the work area is kept clean and free from clutter. With the right safety measures in place, laser cutters and engravers can be used to create incredible designs without putting your health at risk.

Benefits of CNC digital knife cutting machines for cutting things

To conclude, precision and efficiency are critical in the nowadays manufacturing industry. CNC digital knife cutting machines are a versatile and reliable solution for cutting various materials, including textiles and plastics. These machines simplify programming and deliver consistent precision, reducing production time and minimizing errors. Along with delivering greater accuracy, they also have a lower risk of workplace injuries than traditional cutting equipment. With the ability to cut through even the toughest materials with exactness, CNC digital knife cutting machines offer a cost-effective and efficient solution for staying ahead of the curve.